|

Home › Solutions › SmartIndustrial › IIM-42351 |

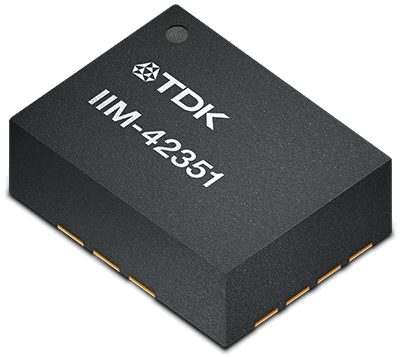

IIM-42351High-Performance 3-Axis SmartIndustrial™ MEMS Accelerometer for Industrial ApplicationsThe IIM-42351 is a 3-axis accelerometer packaged in a small 2.5 × 3 × 0.91 mm (14-pin LGA) package. The IIM-42351 includes multiple capabilities to enable easy, robust and accurate inertial and inclination measurements in Industrial applications, such as low noise, low power, and an output data rate of up to 8 kHz. The IIM-42351's host interface can be configured to support I3C℠ slave, I²C slave, or SPI slave modes. The I3C℠ interface supports speeds up to 12.5 MHz (data rates up to 12.5 Mbps in SDR mode, 25 Mbps in DDR mode), the I²C interface supports speeds up to 1 MHz, and the SPI interface supports speeds up to 24 MHz. The device features an operating voltage range from 3.6 V down to 1.71 V. |

|

|

|

| Product | Type | Package Size (mm) | Gyro Sensing Range (º/sec) | Accel Sensing Range (g) | Interface | Comments | Purchase |

|---|---|---|---|---|---|---|---|

IIM-42351 | 3-Axis Accelerometer | 2.5 × 3 × 0.91 14-pin LGA | N/A | ±16 | I3C℠ / I²C / SPI | Low noise accelerometer for tilt sensing | |

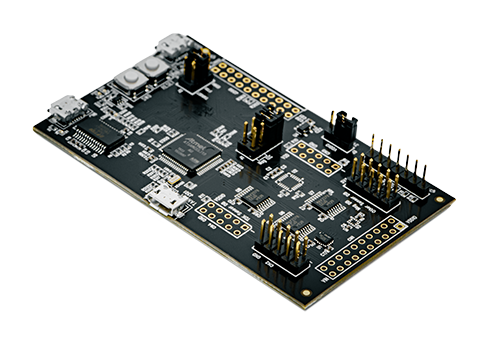

DK-42351 | The DK-42351 is a comprehensive evaluation platform for IIM-42351. It enables quick development and evaluation of the IIM-42351 with the eMD software package. | ||||||

|

|

Precision Agriculture | Construction Equipment | HD Mapping, surveying, and Georeferencing | Industrial, Warehouse, and Automobile Robotics |

|  |  |  |

Bridge GNSS outage and provide terrain compensation inputs during normal operation in various agricultural environments, particularly for equipment navigation, guidance, and positioning.

| Maintain blade and bucket position on bulldozers, excavators, motor-graders, etc. during normal operation. Additionally, the IMU data is coupled with GNSS to constrain position and bridge GNSS outage.

| Precision data enabling the creation of HD maps and surveys, but also provide exact position for stabilization and location.

| Industrial robots use motion data to enable automation, improve efficiency and monitor conditions, as well as the precise motion and vibration measurements produced.

|

| Datasheet / Product Brief | Version | Updated | Download |

|---|---|---|---|

| DS-000441 – IIM-42351 Datasheet | 1.4 | 2022-11-17 |  |

| App Notes & User Guides | Version | Updated | Download |

|---|---|---|---|

| AN-000300 – SmartMotion Platform User Guide | 1.2 | 2024-02-16 |  |

| AN-000393 – IMU PCB Design and MEMS Assembly Guidelines | 1.5 | 2024-02-26 |  |

| Environment / RoHS / Packaging Info | Version | Updated | Download |

|---|---|---|---|

| AN-000393 (pg. 20) – IMU PCB Packaging Info | 1.4 | 2024-01-19 |  |

| QAR-001-00 – InvenSense RoHS 2.0 | 9.1 | 2023-02-08 |  |

| Software (Note: Account required to download) | Version | Uploaded | Download |

|---|---|---|---|

| SmartMotion Installer w/ MotionLink | 4.2.15 | 2024-02-15 |  |

| DK-42351 SmartIndustrial eMD | 1.0.3 |  |

|

|

|

|