|

Home › Solutions › SmartIndustrial › IIM-42653 |

|

|

| Product | Type | Package Size (mm) | Gyro Sensing Range (º/sec) | Accel Sensing Range (g) | Interface | Comments | Purchase |

|---|---|---|---|---|---|---|---|

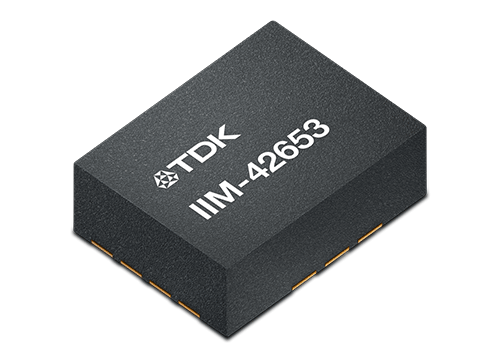

IIM-42653 | 6-Axis IMU | 2.5 × 3 × 0.91 14-pin LGA | ±4000 | ±32 | I3C℠ / I²C / SPI | High FSR ±4000dps, ±32g, Low power, Extended Temperature Range | |

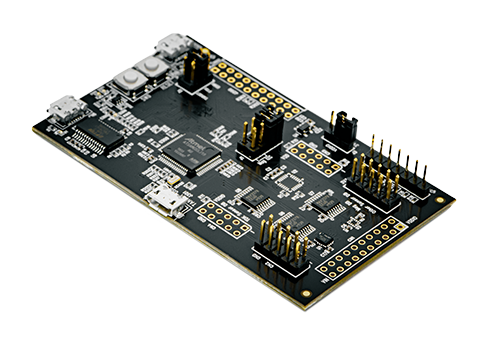

DK-42653 | The DK-42653 is a comprehensive evaluation platform for IIM-42653. It enables quick development and evaluation of the IIM-42653 with the eMD software package. | ||||||

|

|

Precision Agriculture | Construction Equipment | HD Mapping, surveying, and Georeferencing | Industrial, Warehouse, and Automobile Robotics |

|  |  |  |

Bridge GNSS outage and provide terrain compensation inputs during normal operation in various agricultural environments, particularly for equipment navigation, guidance, and positioning.

| Maintain blade and bucket position on bulldozers, excavators, motor-graders, etc. during normal operation. Additionally, the IMU data is coupled with GNSS to constrain position and bridge GNSS outage.

| Precision data enabling the creation of HD maps and surveys, but also provide exact position for stabilization and location.

| Industrial robots use motion data to enable automation, improve efficiency and monitor conditions, as well as the precise motion and vibration measurements produced.

|

| Datasheet / Product Brief | Version | Updated | Download |

|---|---|---|---|

| DS-000529 – IIM-42653 Datasheet | 1.1 | 2024-02-13 |  |

| App Notes & User Guides | Version | Updated | Download |

|---|---|---|---|

| AN-000393 – IMU PCB Design and MEMS Assembly Guidelines | 1.5 | 2024-02-26 |  |

| AN-000300 – SmartMotion Platform User Guide | 1.2 | 2024-02-16 |  |

| Environment / RoHS / Packaging Info | Version | Updated | Download |

|---|---|---|---|

| AN-000393 (pg. 20) – IMU PCB Packaging Info | 1.4 | 2024-01-19 |  |

| QAR-001-00 – InvenSense RoHS 2.0 | 9.1 | 2023-02-08 |  |

| Software (Note: Account required to download) | Version | Uploaded | Download |

|---|---|---|---|

| SmartMotion Installer w/ MotionLink | 4.2.17 | 2024-07-26 |  |

| DK-42653 SmartIndustrial eMD | 1.2.0 | 2024-01-22 |  |

|

|

|

|