|

Home › Solutions › SmartIndustrial › DK-42652 |

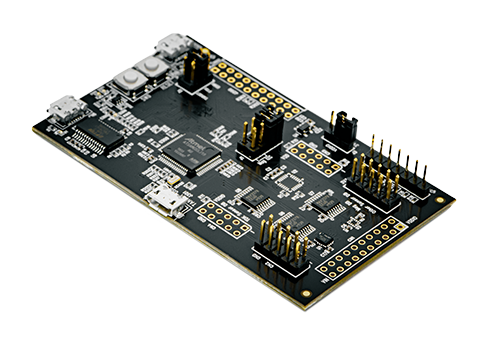

DK-42652Development Platform for IIM-42652The DK-42652 is a comprehensive development platform for IIM-42652, a 6-axis SmartIndustrial™ MotionTracking device that supports an extended operating temperature range. The platform, designed around Microchip G55 MCU can be used by developers for rapid evaluation and development of IIM-42652 based solutions. The DK-42652 includes an on-board Embedded Debugger so external tools are not required to program or debug the G55 MCU. The development kit comes with necessary software including InvenSense Motion Link, a GUI based development tool and embedded Motion Drivers for IIM-42652. Embedded Motion Drivers (eMD) consists of a set of APIs to configure various aspects of the platform including IIM-42652 sensor parameters such as full-scale range (FSR), output data rate (ODR), low-power or low-noise mode, and sensor interface to host (I3C℠, I²C, SPI). MotionLink is a GUI based development tool included with the platform. It can be used to capture and visualize the sensor data from the motion sensor. |

|

|

| Product | Type | Package Size (mm) | Gyro Sensing Range (º/sec) | Accel Sensing Range (g) | Interface | Comments | Purchase |

|---|---|---|---|---|---|---|---|

IIM-42652 | 6-Axis IMU | 2.5 × 3 × 0.91 14-pin LGA | ±2000 | ±16 | I3C℠ / I²C / SPI | Compact, lower power, extended temperature range | |

DK-42652 | The DK-42652 is a comprehensive evaluation platform for IIM-42652. It enables quick development and evaluation of the IIM-42652 with the eMD software package. | ||||||

| App Notes & User Guides | Version | Updated | Download |

|---|---|---|---|

| AN-000300 – SmartMotion Platform User Guide | 1.2 | 2024-02-16 |  |

| AN-000393 – IMU PCB Design and MEMS Assembly Guidelines | 1.5 | 2024-02-26 |  |

| Software (Note: Account required to download) | Version | Uploaded | Download |

|---|---|---|---|

| SmartMotion Installer w/ MotionLink | 4.2.15 | 2024-02-15 |  |

| DK-42652 SmartIndustrial eMD | 1.1.0 |  |

|

|